Concrete Block Manufacturing Methods

This is a very small scale business suitable only for small scale businesses.

Concrete block manufacturing methods. The blending of aggregates cement and water should be done very. The production of concrete blocks consists of four basic processes. Fixed or mobile concrete plants. Then spread the mortar on the footing and begin stacking the blocks beginning in a corner.

Concrete block construction has gained importance and has become a valid alternative to fired clay bricks. The processes involved in the manufacturing of the concrete blocks are as follows. The essential ingredients of concrete are cement aggregate sand gravel and water. Mixing molding curing and cubing.

A concrete block is one among several precast concrete products used in construction. The main criteria for the selection of the ingredients are the desired strength. They are primarily used in the construction of walls. One of the operations block manufacturing was very intriguing.

Concrete plants with planetary mixer or horizontal axis for large productions. They can be produced manually or with the help of machines. On november 7 1997 i visited the marshall concrete plant in christianburg virginia. To lay concrete blocks begin by building a frame with 2x4s and pouring concrete into it to prepare a footing.

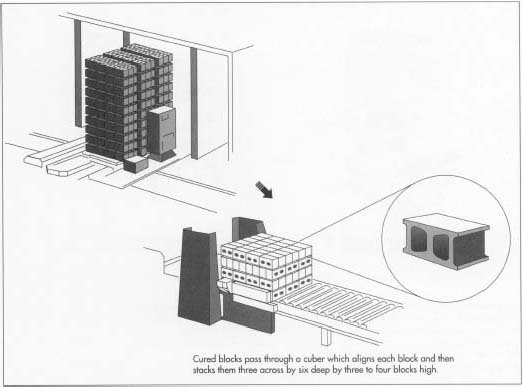

Productions from 30m3 hour to 100 m3 hour. Batching plants for the production of blocks curbs paving stones pipes beams and slabs of concrete ready mix supply for construction works or trucks. Completely manual block manufacturing. The manufacturing process consists of material preparation from storage and from defective blocks machine production loading blocks onto stacks curing unloading from stacks.

Manufacturing process cement concrete blocks can be solid dense or hollow. Cement and sand shall be blended sufficiently and then water is added to the mixture. However the latter is advised when small number of blocks are needed. Besides different sizes and designs can be given to the blocks.

Next prepare cement mortar by mixing water and dried mortar in a 5 gallon bucket. Selection and proportion of ingredients. The blocks are made in the sizes of 12x8x4. Mixing molding curing and cubing are the four basic processes involved in the manufacture of cement.

The advantage of this method is that it needs a very low budget to start the business. It could be done either manually or mechanically. The process of producing concrete blocks can be totally manual. 1 placing hollow concrete blocks 3.

Concrete blocks are produced in a large variety of shapes and sizes.